AMD/Xilinx XC2C Series CPLD: Technical Analysis and Selection Guide

In modern electronic system design, programmable logic devices (PLDs) play a crucial role. Among them, complex programmable logic devices (CPLDs) are widely used in various fields due to their flexibility, low power consumption, and fast startup characteristics. The AMD/Xilinx XC2C series CPLD, as a classic product in this field, has become the preferred choice for many engineers due to its excellent performance and broad applicability.

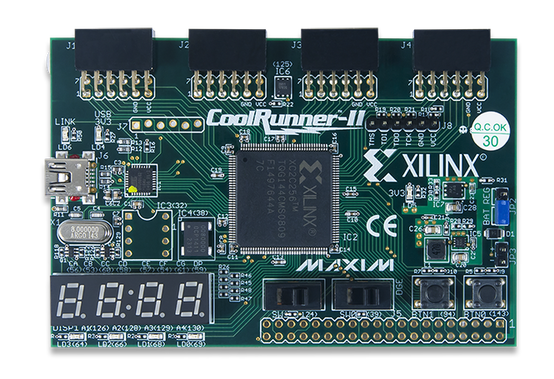

Overview of XC2C Series

The AMD XC2C series is part of the CoolRunner-II series of CPLDs introduced by Xilinx. Utilizing advanced CMOS technology, it provides high-performance, low-power logic solutions. This series of CPLDs is based on an architecture of programmable logic macrocells, programmable I/O units, and programmable internal interconnect networks, enabling the implementation of complex digital logic functions. The core features of the CoolRunner-II series CPLDs include:

●Ultra-low power design: Employing the so-called "Zero Power" technology, the static current can be as low as the μA level.

●High performance: Pin-to-pin propagation delay can be as fast as 3.5 ns.

●High density: Macrocell counts range from 32 to 512, meeting the needs of different complexity design requirements.

●Advanced I/O functionality: Supports a variety of I/O standards and voltage levels.

The working principle of the XC2C series CPLD involves loading configuration data into the chip's storage units to define the behavior of logic units and I/O pins. Once configured, the CPLD performs logic operations based on input signals and outputs the results to external circuits. The series supports multiple programming methods, such as JTAG and SPI interfaces, facilitating user development and debugging.

The AMD/Xilinx XC2C CPLD series is suitable for a variety of application scenarios, including:

1. Industrial control: Implementing complex control logic and interface circuits.

2. Communication systems: Achieving data exchange, protocol conversion, and data parsing functions.

3. Automotive electronics: Designing automotive electronic control units (ECUs).

4. Consumer electronics: Providing low-cost, high-performance logic solutions.

Popular XC2C Series Models Recommendation

Here is a comparison of the key features of several popular models in the XC2C series:

Model | Logic Elements | User I/O Pins | Max Operating Frequency (MHz) | Package Type | Features |

32 | 20 | 200 | VQG44C | Low power, non-volatile storage, supports multiple I/O standards | |

64 | 48 | 200 | CPG56I | High performance, flexible I/O configuration, suitable for medium-scale designs | |

128 | 72 | 250 | VQG100C | High-capacity logic elements, low power | |

256 | 144 | 250 | FT256C | Large-capacity logic elements, suitable for complex designs | |

384 | 144 | 250 | TQ144I | Ultra-high-capacity logic elements, suitable for large-scale systems | |

512 | 144 | 250 | FT256C | Extremely high-capacity logic elements, suitable for highly complex applications |

These models cover a range from the low-power, small-package XC2C32A to the ultra-high-capacity XC2C512, suitable for complex designs. For example, the XC2C32A-6VQG44C is ideal for simple logic control and embedded systems, while the XC2C512-10FT256C is suitable for complex systems requiring a large number of logic resources.

CPLD Chip Selection Guide

When selecting a CPLD chip, the following factors should be considered comprehensively:

1. Logic capacity: Choose the appropriate number of logic elements based on design requirements.

2. I/O pin count: Ensure that the chip provides enough I/O pins to meet system connection requirements.

3. Operating frequency: Select a model that meets the system clock requirements.

4. Power consumption: Prioritize low-power models to extend the device's lifespan.

5. Package type: Choose the appropriate package based on PCB design and space constraints.

CPLD Series from Different Manufacturers

Here are some mainstream CPLD product series from other manufacturers:

Manufacturer | Series | Representative Models | Key Features | Comparative Advantages over XC2C |

Intel (Altera) | MAX II | Low cost, non-volatile, user flash | Integrated user flash, lower cost | |

Lattice | ispMACH 4000ZE | Ultra-low power, small package | Lower dynamic power, smaller package options | |

Microchip (Microsemi) | ProASIC3 | Flash-based FPGA, high density | Higher logic density, hybrid FPGA architecture | |

Intel (Altera) | MAX 10 | FPGA-CPLD hybrid, integrated ADC | Integrated analog functions, higher flexibility | |

Lattice | MachXO2 | Low power, integrated memory | Higher logic density, integrated block memory |

When selecting an alternative, designers need to weigh these differential characteristics against the specific requirements of the project. The XC2C series still maintains a leading advantage in power consumption and performance in pure CPLD applications, especially in applications requiring deterministic timing and fast response.

Conclusion

The Xilinx/AMD XC2C series CPLD, with its high performance, low power consumption, and flexible programmability, is an ideal choice for many application scenarios. When selecting a model, it is necessary to consider logic capacity, I/O pin count, operating frequency, and other factors comprehensively. At the same time, similar products from other manufacturers also provide a wide range of options, which can be compared and selected based on project requirements. With the development of technology, emerging FPGA-CPLD hybrid solutions should also be considered in evaluations, especially in applications requiring additional functions such as storage, DSP, or analog interfaces. The final selection should be based on a comprehensive consideration of specific project requirements, performance indicators, cost targets, and long-term supply assurance.

Website: www.conevoelec.com

Email: info@conevoelec.com