LG Display Evaluates Photolithography OLED Technology

In the display technology sector, OLED technology has always been a focal point for research and development as well as competition among major panel manufacturers due to its excellent display performance and broad application prospects. Recently, LG Display's plan to evaluate photolithography OLED technology, which is free of FMM (Fine Metal Mask), on its existing TV OLED production line in Paju, South Korea, has attracted widespread attention in the industry.

Overview of Photolithography OLED Technology

Photolithography OLED technology is significantly different from traditional FMM OLED technology in the pixel definition layer. Traditional FMM OLED technology uses fine metal masks to precisely deposit organic compounds onto specific areas. However, this method is limited by the mask size, and it has limitations in pixel density and substrate size expansion. In contrast, photolithography OLED technology first carries out full-surface evaporation of a single primary color, then selectively removes the parts on the substrate that do not need to be retained. This process is repeated three times to achieve full-color patterning of the three primary colors. The advantage of this technology is that it can increase the aperture ratio of the pixel emission area, thereby extending the life of OLEDs. For example, JDI claims that the aperture ratio of OLEDs produced by its eLEAP technology is 60%, which is twice the existing 28%.

Photolithography OLED technology is significantly different from traditional FMM OLED technology in the pixel definition layer. Traditional FMM OLED technology uses fine metal masks to precisely deposit organic compounds onto specific areas. However, this method is limited by the mask size, and it has limitations in pixel density and substrate size expansion. In contrast, photolithography OLED technology first carries out full-surface evaporation of a single primary color, then selectively removes the parts on the substrate that do not need to be retained. This process is repeated three times to achieve full-color patterning of the three primary colors. The advantage of this technology is that it can increase the aperture ratio of the pixel emission area, thereby extending the life of OLEDs. For example, JDI claims that the aperture ratio of OLEDs produced by its eLEAP technology is 60%, which is twice the existing 28%.

LG Display's Evaluation Plan

LG Display's choice to evaluate photolithography OLED technology on its Paju TV OLED production line is based on unique considerations. Currently, the utilization rate of LG Display's Paju TV OLED production line is relatively low, at around 30%. Since WOLED and photolithography OLED share certain similarities in equipment and principles, developing photolithography OLED on the idle TV WOLED production line can lay a foundation for future technological transformation at a lower cost. In addition, LG Display also plans to introduce more research equipment needed for the evaluation of FMM-free technology. It will decide whether to build a mass production line based on the evaluation results.

Industry Background and Impact

FMM OLED technology is currently the main production technology for small and medium-sized OLED panels. However, as display technology continues to evolve, its limitations in medium and large-sized panels and high pixel density areas are gradually revealed. The emergence of photolithography OLED technology provides a new solution to this problem. If LG Display can successfully achieve mass production of photolithography OLED technology, it will be able to enhance its competitiveness by utilizing existing production lines without having to make a new round of large-scale investments. Nevertheless, photolithography OLED technology is not yet fully mature and still faces challenges such as technological verification. Despite this, this evaluation plan is still regarded as an important move by LG Display to prepare for investment in next-generation technology.

Summary and Outlook

LG Display's evaluation plan for photolithography OLED technology in Paju is not only a breakthrough attempt in existing production processes but also an active exploration of future display technology development. The high aperture ratio and advantages of photolithography OLED technology in medium and large-sized panel production give it a broad application prospect. Although the technology has not yet completed mass production verification at present, with continuous investment and research by panel manufacturers such as LG Display, it is believed that photolithography OLED technology will have the potential to be widely applied in the future and bring about new changes to the display field.

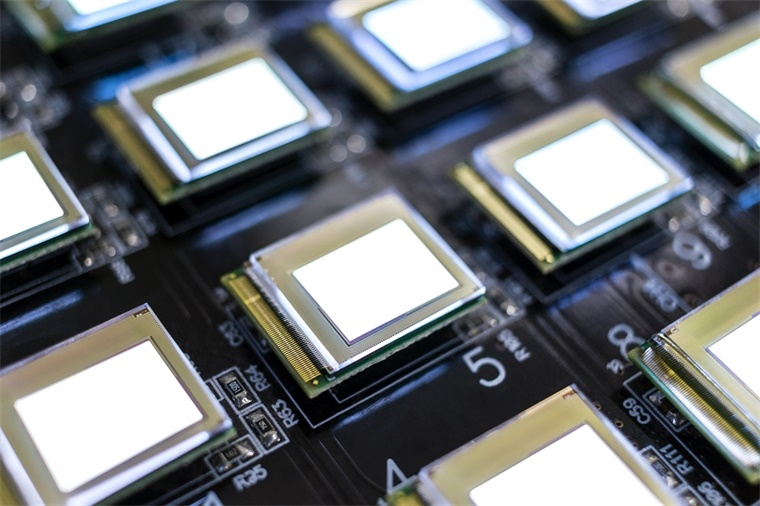

Conevo ICs Supplier

Conevo is a top-tier semiconductor chip distributor, offering a vast array of high-quality ICs such as FPGA, memory, PMIC, and DSP. With a robust supply chain and extensive inventory, we ensure quick and efficient delivery of the right components. Here are some of our hot recommended IC models:

● ADM3485EARZ: A robust RS-485 transceiver with enhanced ESD protection.

● Z8523016VEG: A versatile UART/I2C/SPI controller for reliable communication.

● INA128UA: A precision instrumentation amplifier with high input impedance and low noise.

Website: www.conevoelec.com

Email: info@conevoelec.com