Mastering ADCs: A Deep Dive into Analog-to-Digital Converters

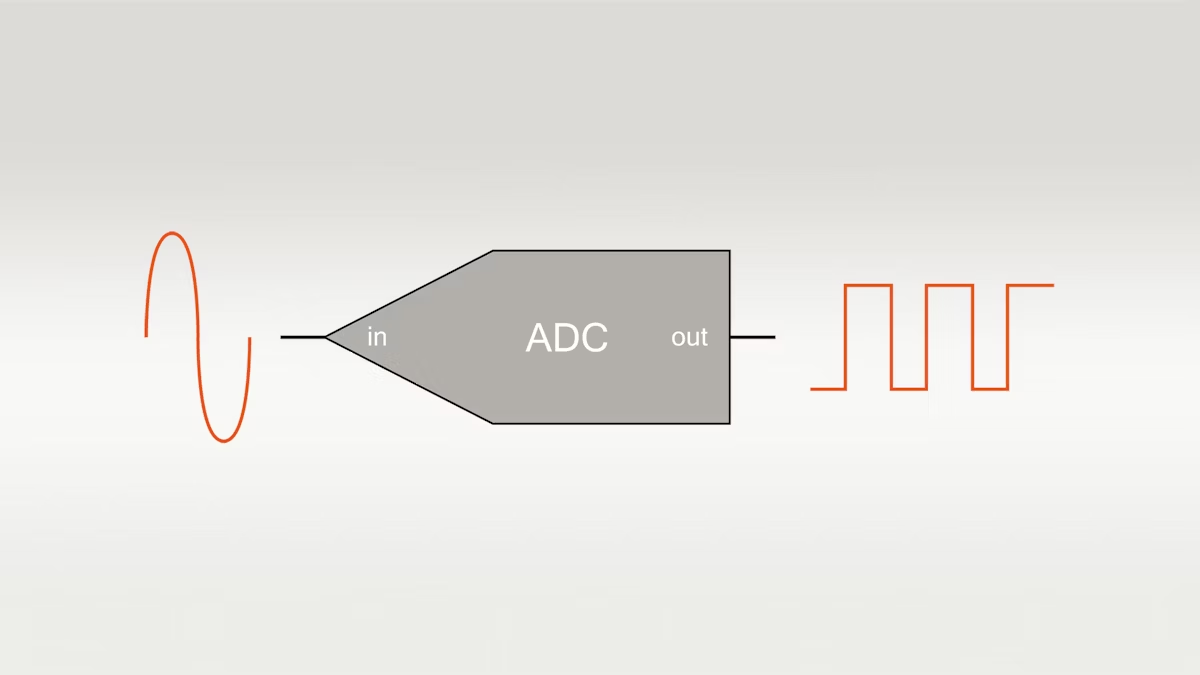

In modern electronic technology, the Analog-to-Digital Converter (ADC) is an essential component. It converts continuous analog signals into discrete digital data, enabling digital systems to process, store, and transmit these signals. This process is crucial for transforming real-world signals (such as sound, temperature, and pressure) into digital form.

Detailed Explanation of Analog-to-Digital Converter (ADC)

The primary function of an ADC is to convert analog signals (such as voltage and current) into digital signals. This conversion process includes three key steps: sampling, quantization, and encoding.

The primary function of an ADC is to convert analog signals (such as voltage and current) into digital signals. This conversion process includes three key steps: sampling, quantization, and encoding.

● Sampling: The ADC samples the analog signal at fixed time intervals, known as the sampling rate. According to the Nyquist theorem, the sampling rate should be at least twice the highest frequency of the signal to avoid aliasing.

● Quantization: The sampled signal is assigned to different digital levels, a process called quantization. The precision of quantization depends on the ADC’s resolution, typically expressed in bits.

● Encoding: The quantized signal is then encoded into binary digits for processing by digital systems.

ADCs are widely used in various applications, including audio processing, medical imaging, industrial control, and IoT devices. For example, in audio equipment, high-resolution ADCs can capture subtle signal changes, providing higher-quality audio.

Distinguishing ADC from DAC

Data Converter ICs serve as the bridge between the analog and digital domains. ADCs convert analog signals into digital signals, while Digital-to-Analog Converters (DACs) convert digital signals back into analog signals. The differences between the two are as follows:

ADCs convert continuous analog signals into discrete digital signals. In this process, the input of an ADC is an analog signal, and the output is a digital signal, suitable for signal acquisition and processing.

Unlike ADC, DACs convert digital signals back into continuous analog signals. Note that the input of a DAC is a digital signal, and the output is an analog signal. DACs play a vital role in devices that need to output analog signals, suitable for signal output and display.

Popular ADC Chip Selection and Recommendations

Choosing the right ADC chip is crucial for ensuring device performance. Here are some popular ADC chip models and their features:

Model | Resolution (bits) | Sampling Rate (SPS) | Features |

24 bits | 500kSPS | Ultra-low noise, suitable for industrial sensors | |

Analog Devices AD7606 | 16 bits | 200kSPS | High-speed, high-precision, suitable for industrial applications |

Maxim Integrated MAX1112 | 12 bits | 200kSPS | Low power, suitable for battery management systems |

Microchip Technology MCP3424 | 18 bits | 15SPS | High precision, suitable for high-precision measurements |

STMicroelectronics STM32F411 | 12 bits | 1MSPS | Integrated ADC, suitable for embedded systems |

When selecting an ADC chip, consider the following points:

1. Resolution: Choose the appropriate resolution based on application needs. High resolution is suitable for high-precision scenarios.

2. Sampling Rate: For high-speed signal processing, select an ADC with a high sampling rate.

3. Power Consumption: In low-power applications, choose a low-power ADC to extend battery life.

4. Noise and Precision: For high-precision measurements, select an ADC with low noise and high precision.

Conclusion

ADCs are indispensable components in modern electronic systems, converting analog signals into digital signals to enable precise processing of the real world by digital systems. By understanding the working principles, applications, and differences from DACs, engineers can better select ADC chips that meet their application needs. As technology continues to advance, the applications of ADCs in audio processing, industrial control, and IoT will become even more extensive.

Website: www.conevoelec.com

Email: info@conevoelec.com